Indigenous equipment for blood banks and biomedical research

Have you ever wondered where body organs, such as kidneys, hearts, and eyes, that are meant for transplantation are stored, and what happens to them while they wait for a new home?

Our story begins where technology becomes the guardian of human life, from the coldest temperatures to the warmest hopes, from small laboratories to vast national projects.

Join us on a journey to the world of Danesh Pajoohesh Fajr, where Iranian innovation speaks the language of life and saving lives and a journey to the place where human organs are stored at 86 degrees below zero.

Danesh Pajoohesh Fajr is among the oldest and one of the pioneering companies in Iran that manufactures equipment for storing plasma, blood products, body organs and tissues.

It has been beating at the heart of Iran's biomedical industry for over two decades, its name synonymous with trust and innovation.

Our company was founded in Tehran in 1995, the goal of establishing this company was to manufacture medical and laboratory equipment related to blood banks and the blood transfusion organization. We realized that the equipment used by the blood transfusion organization wasn't anything extraordinarily complex. This complex was being imported from abroad.

In any case, we began designing, drafting plans and carrying out the work, given that I'm a mechanical design engineer myself, specializing in solid mechanics. We embarked on this project along with my brother, who had some information due to his involvement with the blood transfusion organization, and was very curious about how these devices were built. We started this venture under these circumstances.

We began from a small office in Tehran and approached the blood transfusion organization. At that time, we took our designs and ideas, built a small prototype, showed it to them, and they trusted us, entering into a contract with us.

This effort has led us to where we are today. We are now proud to say that the Danesh Pajoohesh company has manufactured close to 20,000 units of various models of blood bank refrigerators for storing blood bags, platelet incubators, plasma storage freezers, and the A1 cell culture incubator and minus 80 degrees centigrade ultra low temperature freezers for preserving tissues and bodily organs, which are present in most research centers across Iran.

It is our honor that we have installation and commissioning representatives as well as service teams across Iran for this equipment, and we are actively working in this field.

And most interestingly and importantly, some of the devices we first built nearly 27 or 28 years ago are still operational and in use at certain centers.

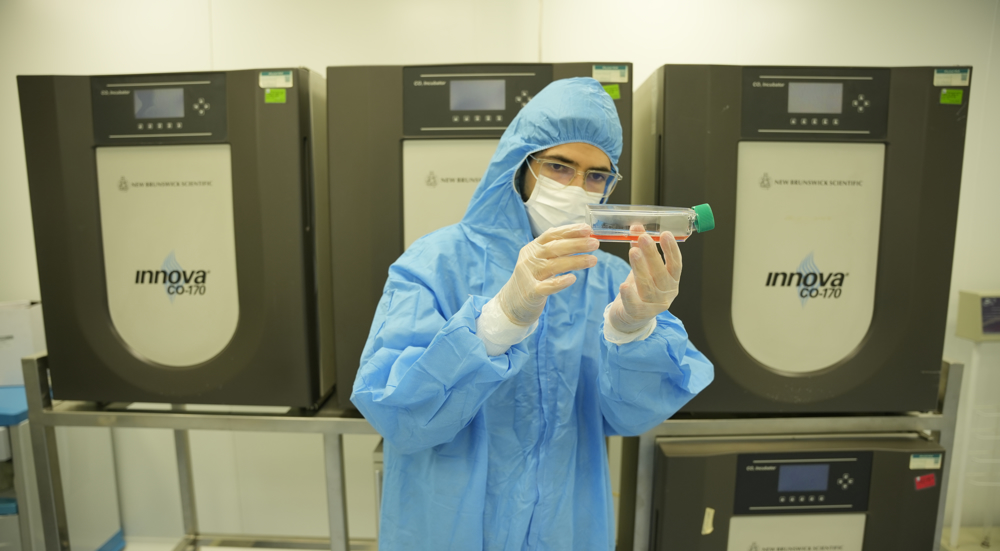

Currently, we are also producing research equipment, as I mentioned, such as the A1 cell culture incubator used for producing drugs like clotting factors and insulin In pharmaceutical centers for the first time in Iran, we manufactured and delivered our device to them, and it is being used.

Other pharmaceutical centers also use our equipment, including our minus 80 degree centigrade, ultra low temperature freezers. For the first time, and in response to the country's needs, we even designed it with two separate refrigeration cycles.

Due to the servicing challenges in our country and the device's reliance on high technology, we innovated by using two independent systems for the first time. This ensures that if one cycle fails, the other continues to operate fully, preventing any damage to the valuable blood products or research materials. This is a distinct advantage over similar foreign devices.

Of course, this approach is more costly for us, but given the operational conditions and our commitment to localization, it stands as a positive achievement for our company, and a source of pride for our work in this field.

Furthermore, in the production of the cell culture device, it is noteworthy that there are no more than three or four companies worldwide that manufacture this equipment, one of which is the Danesh Pajoohesh Fajr Company. We are proud to have produced this device, and it is now being utilized in pharmaceutical centers.

Mohammad Hassan Bastami, Danesh Pajoohesh Fajr, CEO

What you just heard was just part of the long and challenging path of the Danesh Pajoohesh Fajr company, the path of turning an idea into a series of national and international achievements.

The CEO clearly explained how the company managed to find its special place in Iran's biomedical industry through innovation and indigenous knowledge.

But what is plasma factor VIII and what is its significance?

Plasma, the golden yellow component of blood is rich with Vital Proteins. Among these proteins, factor VIII plays a pivotal role in the blood clotting process, and its absence puts hemophilia patients at risk of dangerous bleeding.

The production cycle of factor VIII from plasma begins with the collection of plasma from healthy donors. The samples undergo rigorous virological and safety screening. After which, using advanced separation methods, the various plasma proteins are isolated.

At this stage, factor VIII is extracted as cryoprecipitate and purified using modern chromatography technology. To make the product safe viral inactivation processes are carried out, including nanofiltration and controlled heat treatment, which guarantee that the final medication is free from pathogens.

In the end, the purified factor VIII is packaged as a lyophilized powder or a ready-to-use solution. Each vial with a specific dosage is prepared for injection into patients with hemophilia A.

In the research and development R&D unit of our company, we have strived to develop and manufacture equipment for the country under the banner of the Danesh Pajoohan Company to support the pharmaceutical sector and the storage of plasma and blood products nationwide.

The device you see in the image is a blast device, a plasma freezer. It can reduce the temperature of plasma from approximately plus 50 degrees Celsius down to minus 50 degrees Celsius in under an hour, typically within 45 minutes.

This unit features four shelves. Each shelf can hold six plasma units totaling 24 units. Therefore 24 plasma units can reach minus 50 degrees Celsius in less than one hour. Every component of this device has been designed and manufactured by the company's engineers. This includes the refrigeration systems, the electronic systems, and, the embedded software programming.

The data loggers are also entirely built by the Danesh Pajoohan Company by Iranian engineers. All temperature data and device information is logged by the device. You can extract graphs from it. Temperature graphs are displayed. It has a USB port for downloading data in formats like PDF and Excel, for viewing graphs and also for monitoring device alarms. All device alarms are displayed in real time on the unit itself.

The device you see in this image is the Danesh Pajoohan Company’s minus 80 degrees Celsius freezer. This single door freezer features a dual independent refrigeration system, two separate cooling circuits. It can bring the internal temperature down to minus 80 degrees Celsius.

This device is used in research centers in biological, bio-technological and pharmaceutical fields, as you can also observe in this device; it has two independent cooling circuits visible in the image, along with the data logger that monitors the entire system.

This system can log temperature data for up to two years and store up to 8000 alarm events internally. Look here. It shows an error, for example, a sensor fault and a cooling circuit. These are tests conducted by our own team. We can see everything here, upper and lower temperature limits and all other parameters. This also has a USB port for Excel output.

Shantia Mirrasoli, R&D Head, Danesh Pajoohesh Fajr

This device is the plasma recoverer, which can lower the plasma temperature from positive 25 degrees, which is room temperature, to negative 25 degrees in a period of three hours. It has four completely independent chambers, which means you can place a plasma bag in each chamber.

It is designed for plasma volumes from 150 to 200 milliliters, and features four completely separate doors. The device you see in this image is the A1 cell culture incubator. It was used for producing factor VIII and the COVID-19 vaccine during the peak of the COVID-19 pandemic in our country, when cases surged, they utilized this very device to manufacture the COVID-19 vaccine domestically.

The device operates at 28 degrees Celsius. It features a rolling bottle system. It can culture drugs using the nutrient medium poured into the bottles. These bottles rotate and at temperatures of 40 degrees Celsius and 24 degrees Celsius, bacteria are introduced into the bottles via filters, which aids in improving the cell culture process.

Shantia Mirrasoli, R&D Head, Danesh Pajoohesh Fajr

Design, Development & Manufacturing

Our manufacturing process in the factory consists of several units. There is the mechanical unit where the device's body is produced. We have the refrigeration unit which designs and installs our cooling systems and the Electrical and Electronics unit.

Of course, before entering production, our design and engineering unit is highly active. It consists of university elites from our own country who worked hard here designing the product from scratch. They then hand over the designs to our production units.

We have also done reverse engineering. There were devices that were reverse engineered, but we no longer rely on that method. For those devices that we did reverse engineer, we have fixed their flaws. Originally American and European devices, they are now being produced to the highest standards for the Iranian blood transfusion organization nationwide, as well as hospitals across the country.

We have had significant achievements in the field of cell culture equipment. We have designed at least five distinct products in this area, from design to manufacturing, and they are now operational in various centers across the country.

In our field, our annual production volume isn't very high because manufacturing our devices is complex. However, our factory is modern and well equipped. The machinery and facilities we have are excellent. Similar factories we have seen in Europe and China were not superior to ours, but because these devices have specific complexities, our current annual production output is limited.

The most important point is that the countries producing these devices have sanctioned us and refused to sell them to us, yet we have managed not only to design and produce these devices, but also to improve upon them.

We can supply them to all centers in need across the country. This is a very positive point, and we are proud to be serving our nation in this capacity.

Noorali Badpour, Design and Development VP

The strategic calculus driving Iran-Kazakhstan ties

EU member states agree to impose indefinite freeze on Russian assets

Israeli military conducts new ground incursion in Syria’s Quneitra

Israeli forces kill Palestinian teenager in Gaza amid truce violations

Talk of Israeli attack on Hezbollah in line with Israel’s agenda: Lebanese MP

Scrutiny grows over Trump’s health after drowsy public appearances

VIDEO | Press TV's news headlines

Dollar no longer safe haven, US economic fragilities erode trust in it: Economist

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website