Iran’s cement revolution and rise as regional powerhouse

Over the decades since the Islamic Revolution in 1979, Iran has developed significant capabilities in cement production, placing the country among the top producers in Asia and the Middle East.

As one of the foundational industries in any modern economy, cement plays a central role in the construction of infrastructure, urban development, and housing.

Iran’s cement industry stands as a cornerstone of the country’s industrial development and a critical driver of economic growth.

Today, it has more than 70 active cement factories with a nominal annual production capacity of approximately 90 million tonnes, though practical output may be slightly lower due to operational challenges such as energy limitations.

Iran’s cement industry has not only grown in capacity but also in export capability. Annually, the country exports between 12 and 15 million tonnes of cement, reaching markets in Iraq, Afghanistan, Central Asia, Oman, and Qatar.

The export market highlights Iran’s ability to produce high-quality cement at a scale that can meet international demand, while also contributing to the country’s economic interactions with neighboring nations.

Historically, cement was introduced to Iran through foreign projects, including the construction of churches, embassies, and port facilities.

However, by the early 20th century, the rapid expansion of infrastructure, including the construction of a nationwide railway network, created a pressing demand for domestic cement production.

The Iranian government responded to this need by establishing the first cement factories, beginning with the Tehran-based “Sement Rey” plant in the early 1930s.

This initial investment laid the groundwork for the growth of a domestic cement industry capable of meeting the country’s expanding construction requirements.

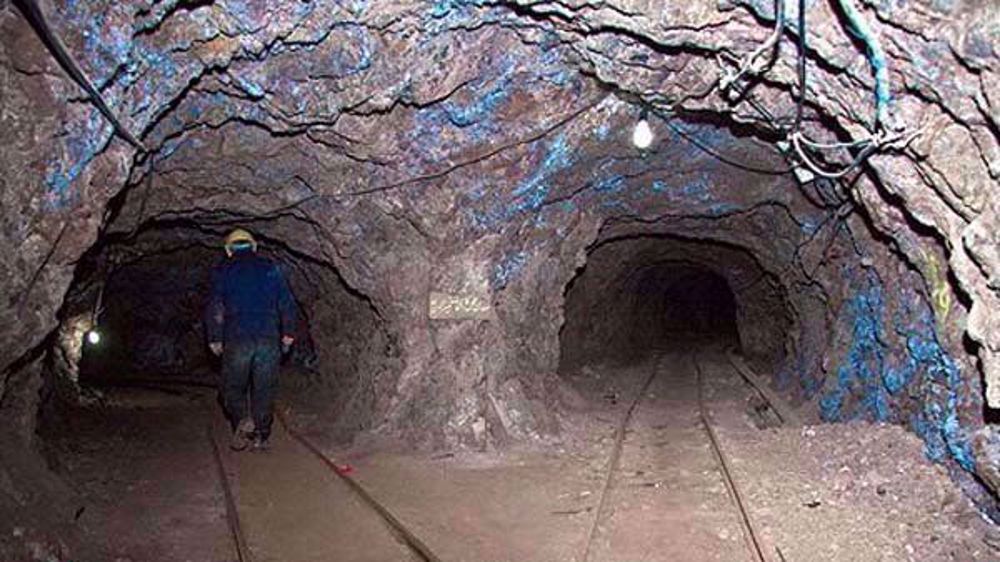

Geographically, Iran is well-positioned for cement production. The country is surrounded by limestone-rich mountain ranges, providing an abundant supply of the essential raw materials needed for manufacturing cement.

Recognizing this advantage, the government undertook careful studies to identify suitable sites for factories and to assess available reserves. Over time, these investments created a solid industrial base and the technical expertise necessary for efficient production.

By the mid-20th century, Iran had developed multiple cement plants, each increasing the country’s annual production capacity.

Despite interruptions caused by global events such as World War II, the sector steadily expanded, and by the years following the revolution, the country had established a network of factories that could serve both domestic and regional markets.

The industry has demonstrated resilience and adaptability. From its early days as a net importer of cement, Iran has transformed into one of the top 10 producers in the world. By 2016, it had become the third-largest producer in Asia and the leading producer in West Asia.

This remarkable shift underscores the country’s ability to scale production, develop technology, and manage supply chains effectively.

Approximately 92% of the total cement produced in Iran since the inception of the industry has been manufactured after the revolution, reflecting a period of rapid industrialization and investment in domestic capabilities.

Cement production in Iran supports a wide range of economic activities. It is essential for building roads, bridges, tunnels, housing, and public infrastructure.

The availability of domestic cement reduces reliance on imports, lowers construction costs, and supports the growth of ancillary industries such as concrete, steel, and construction equipment.

The industry also generates employment, both directly within factories and indirectly through construction projects, logistics, and export activities.

Iranian cement factories have demonstrated technical competence and operational sophistication. The sector has absorbed advanced machinery from international partners in its early years, while gradually building domestic expertise in plant management, quality control, and production optimization.

The evolution of factory capacity from small initial plants producing tens of thousands of tons per year to modern facilities capable of producing millions of tons reflects a strong institutional knowledge base and industrial capability.

The country’s geographic advantage, combined with its industrial know-how, enables a production strategy that is both efficient and sustainable. Limestone and other raw materials are abundant and strategically distributed, allowing factories to minimize transport costs and energy consumption.

This natural advantage, coupled with human capital and experience, positions Iran to expand its domestic market share and strengthen its role in regional cement exports.

The industry has also demonstrated flexibility in responding to shifting market conditions. Despite recent challenges such as reduced domestic demand, currency fluctuations, and the temporary loss of Iraq as a major export destination, the sector maintains the infrastructure and production capacity to adapt quickly.

Overall, Iran’s cement industry is a testament to the country’s industrial potential. It combines abundant natural resources, technical expertise, and a long history of industrial development to produce a critical commodity that underpins economic growth.

Its ongoing capacity to support large-scale infrastructure projects, domestic construction, and regional trade highlights the sector’s enduring economic significance and strategic value for national development.

This combination of resources, technical expertise, and strategic positioning underscores Iran’s capacity not just to produce cement efficiently, but to use the industry as a foundation for broader economic development and industrial leadership in the region.

Iran to those silent on anti-Iran war: History will judge you

IRGC navy drone unit launches massive attack on key US air base

Pezeshkian: Enemies will take dream of Iran’s surrender to grave

US confirms Iran destroyed $300m radar system in Jordan

Imam Khamenei: A legacy forged in unshakable faith, bravery and steadfastness

Iran Navy announces wave of fresh drone strikes on US bases, strategic Israeli sites

Pezeshkian reaffirms Iran’s commitment to defend sovereignty, pursue lasting peace

Many US troops exploring ways to evade fighting in war on Iran: Anti-war activist

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website