Magnetic revolution: Iran’s nano-solutions driving cleaner and greener oil industry

By Ivan Kesic

At the intersection of global energy demands and environmental responsibility, Iranian scientists are quietly spearheading a revolution of its own kind by developing microscopic agents capable of purifying crude oil with unparalleled efficiency and ecological sensitivity.

In the intricate world of petroleum refining, one persistent and costly challenge remains: separating water from crude oil – a mixture intractably held together by natural chemicals.

Historically, this issue has been tackled using chemical demulsifiers, which, while effective, often leave behind toxic residues. Now, thanks to advances in nanotechnology emerging from Iran’s research laboratories, this process is undergoing a transformative shift.

Researchers from leading institutions such as Amirkabir University of Technology and the Research Institute of Petroleum Industry (RIPI) have synthesized a new generation of eco-friendly, magnetic nano-demulsifiers.

Crafted from natural materials like cotton and chitosan, these innovative compounds not only break down resilient water-in-oil emulsions with exceptional efficiency but can also be magnetically retrieved and reused, offering a compelling combination of high performance, cost savings, and environmental stewardship.

This exploration delves into the science behind these breakthroughs, their significant implications for the energy sector, and how they position Iran at the forefront of sustainable petroleum technology.

The problem of water in oil

Crude oil extracted from reservoirs rarely comes pure. It typically appears as a stable emulsion, with microscopic water droplets dispersed throughout the oil, held together by natural surfactants such as asphaltenes and resins.

These water-in-oil emulsions create major challenges for the energy industry. They accelerate corrosion in pipelines and processing equipment, poison costly refinery catalysts, increase transportation costs by hauling unnecessary water, and complicate downstream processing.

For decades, chemical demulsifiers, specialized surfactants or polymers, have been employed to destabilize these emulsions.

Although effective, these traditional agents raise environmental concerns. They can be toxic, difficult to recover after use, and often contribute to secondary pollution in the separated water streams.

These limitations have fueled a pressing global demand for more sustainable, efficient, and intelligent separation technologies that reduce both operational costs and ecological impact.

Nanoscale solution to a macro-scale challenge

The advent of nanotechnology has unlocked powerful new tools for manipulating matter at the molecular level, offering innovative solutions to longstanding industrial problems.

Nanoparticles boast exceptionally high surface area-to-volume ratios and tunable surface chemistry, enabling them to interact precisely at the interface where oil and water meet.

Globally, researchers have recognized the promise of magnetic nanoparticles for demulsification, as their inherent properties allow for targeted manipulation and easy recovery using external magnetic fields.

This magnetic retrieval capability is a game-changer, moving beyond disposable chemical agents toward a reusable, circular process in oil purification.

Iranian research teams have masterfully embraced this scientific frontier, enhancing these nanomaterials with eco-friendly features to develop solutions that combine efficacy with green chemistry and sustainable industrial practice.

Cellulose breakthrough: Green and magnetic

A landmark achievement from Iranian scientists, published in 2024 in Environmental Pollution, is the synthesis of recyclable magnetic cellulose nanocrystals.

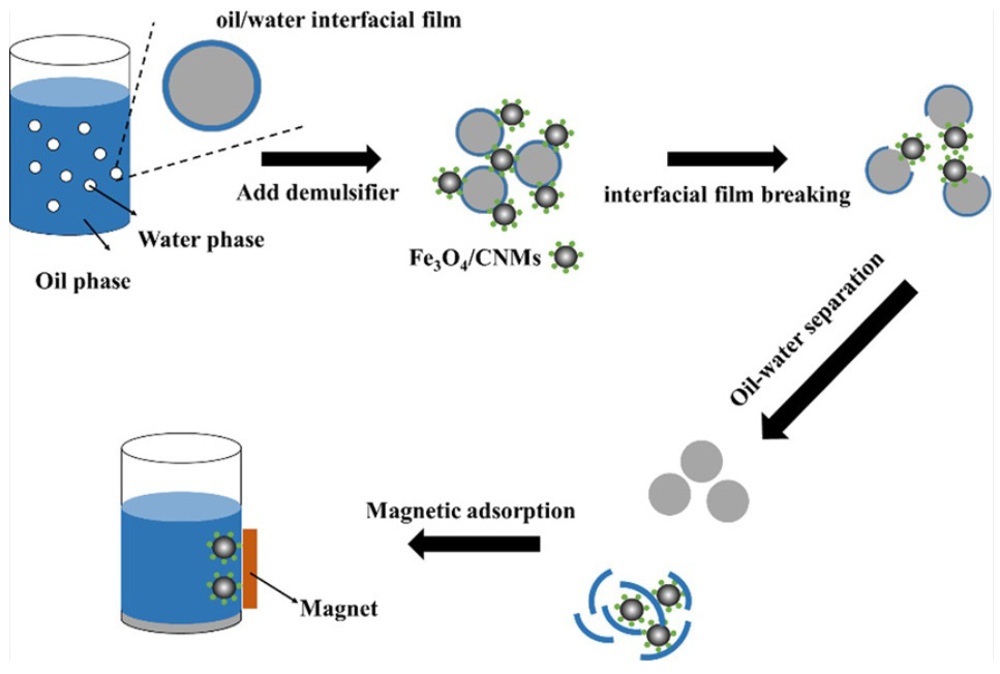

Led by Zahra Amiri and Alimorad Rashidi, the team engineered these hybrid nanoparticles by anchoring magnetic iron oxide (Fe₃O₄) onto nanocrystals derived from cotton – an abundant, renewable biopolymer.

This innovation exemplifies an elegant synergy of performance and sustainability.

The magnetic cellulose nanocrystals demonstrated outstanding demulsification efficiency, achieving 100% water separation at 50°C without magnetic aid and 90% efficiency at 20°C when assisted by a magnet.

Even more impressively, these nanoparticles could be magnetically recovered and reused for up to four cycles without significant loss of performance, dramatically reducing waste and operational costs.

By leveraging cellulose as the base material, the researchers ensured the demulsifier is biodegradable and low in toxicity, directly addressing the environmental issues posed by conventional chemical agents.

Expanding the nano-toolkit: Chitosan and modified silica

Iran’s pursuit of sustainable nano-demulsifiers extends beyond a single approach, showcasing a dynamic research ecosystem exploring diverse material platforms.

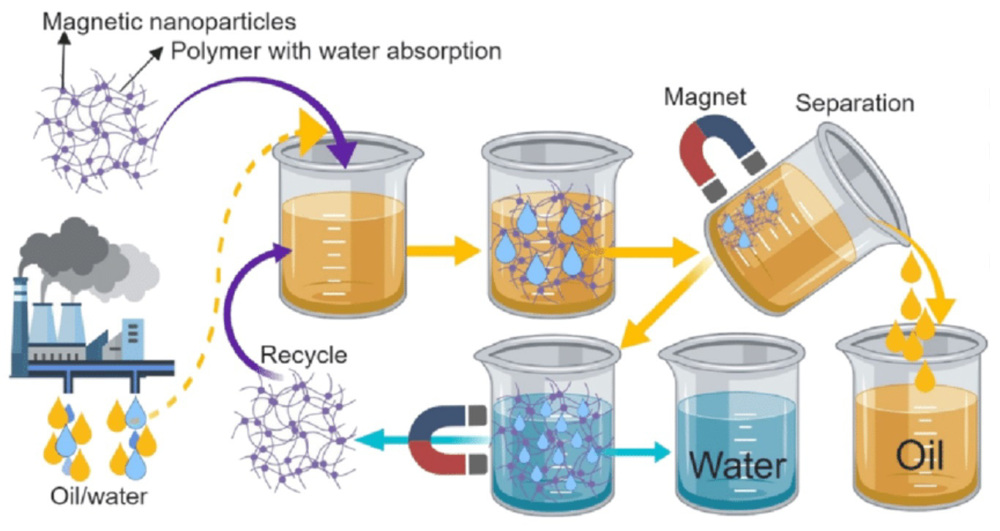

In parallel studies, researchers have synthesized a magnetic demulsifier using manganese ferrite nanoparticles coated with chitosan, a biopolymer derived from shellfish waste.

This MnFe₂O₄ NPs@CS composite exhibits superparamagnetic and superhydrophobic properties, enabling it to effectively adhere to water droplets within oil emulsions via electrostatic attraction.

The demulsifier demonstrated impressive durability, maintaining high performance over at least seven reuse cycles, highlighting both economic and environmental advantages of recyclable materials.

Another promising avenue involves modifying abundant silica (SiO₂) with benign cationic surfactants such as benzalkonium chloride, creating an amphipathic, biodegradable demulsifier.

Research shows that this modified silica significantly reduces interfacial tension between oil and water, achieving complete water separation, especially at elevated temperatures.

These complementary approaches illustrate a strategic, multifaceted effort to solve the demulsification challenge, leveraging diverse material sciences to optimize efficiency, recyclability, and ecological compatibility.

Mechanics of magnetic purification

The superior performance of these magnetic nano-demulsifiers relies on a sophisticated interplay of physical and chemical mechanisms.

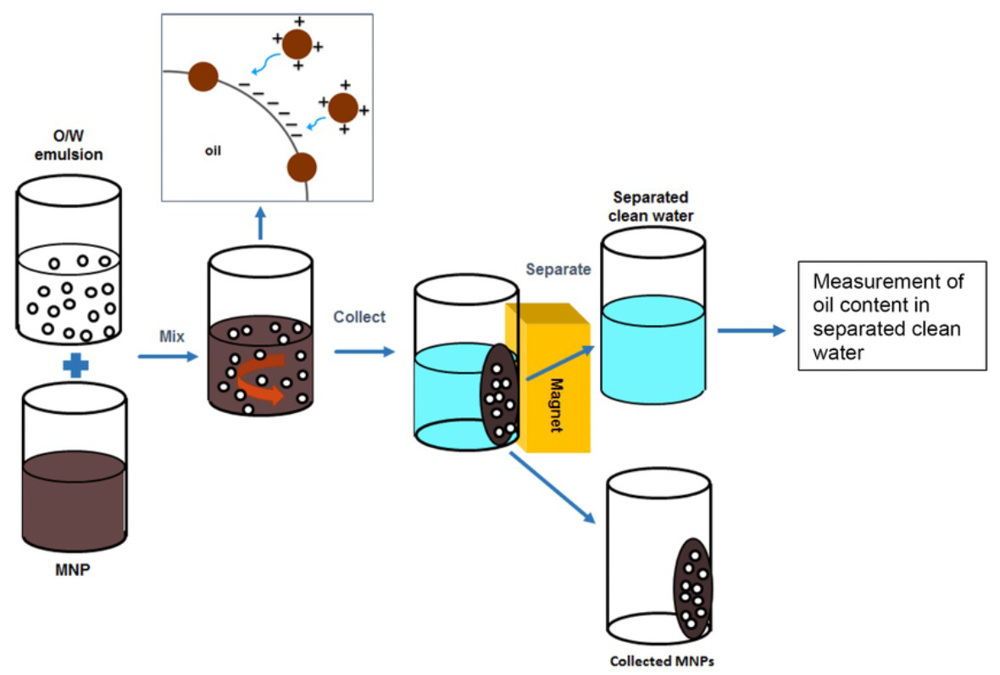

When introduced to water-in-oil emulsions, nanoparticles migrate to the oil-water interface, drawn by polarity differences.

Their presence disrupts the rigid film formed by natural emulsifiers like asphaltenes, reducing the interfacial tension that stabilizes the emulsion.

This destabilization encourages dispersed water droplets to coalesce into larger droplets that can settle out by gravity due to their increased size and weight.

Crucially, the magnetic component enables a clean, efficient process closure: after demulsification, an external magnet quickly and thoroughly retrieves the nanoparticles from the treated mixture.

This magnetic recovery prevents the nanoparticles from becoming contaminants, allows for their regeneration, and supports multiple reuse cycles—creating a process that is both economical and environmentally responsible.

Environmental and economic resonance

The impact of these Iranian innovations extends far beyond laboratory achievements, addressing critical challenges and shifting priorities in the global energy sector.

Environmentally, the move toward biodegradable, low-toxicity base materials such as cellulose and chitosan, combined with near-total recoverability of the demulsifying agents, marks a significant step toward greener petroleum processing.

This technology reduces harmful chemical residues in wastewater, lowers additive volumes needed, and aligns with increasingly stringent international regulations on industrial emissions and waste management.

Economically, the high demulsification efficiency, often achieved in shorter timeframes and at lower temperatures, translates into increased operational throughput, decreased energy consumption for heating emulsions, and cost savings due to material recyclability.

For oil-producing countries, domestic development of such advanced nanomaterials enhances technological self-reliance, reduces dependence on imported specialty chemicals, and opens potential export markets for high-value nanotechnologies in the energy sector.

Testament to strategic research and development

The emergence of these advanced nano-demulsifiers from Iran is no coincidence but a reflection of deliberate, strategic investment in research and development within the energy and nanotechnology fields.

Institutions like the Research Institute of Petroleum Industry (RIPI) play a vital role, bridging fundamental academic research at universities such as Amirkabir University of Technology with the practical demands of the national petroleum industry.

This collaborative framework fosters direct application of cutting-edge nanoscience to solve pressing industrial challenges.

Regular publication of these findings in respected international journals underscores both the quality of the research and Iran’s active engagement in the global scientific discourse on sustainable energy.

By cultivating domestic expertise and innovation in this critical arena, Iran not only addresses its own industrial needs but also asserts its position as a contributor of meaningful, sophisticated solutions to worldwide energy and environmental issues.

🇮🇷 Iranian researchers create eco‑friendly magnetic nano‑demulsifiers to purify oil

— Iran First (@IranFirst_PTV) January 2, 2026

This innovation effectively breaks tough “water-in-oil” emulsions in petroleum industries, offering a greener solution for the environment and energy sector.#IranFirst🇮🇷 pic.twitter.com/uff1Jum8PY

Navigating the path from lab to field

While the laboratory results are profoundly promising, transitioning from successful bench-scale experiments to widespread industrial adoption involves overcoming a series of complex challenges.

Scaling up production is a major hurdle, as synthesizing these nanomaterials in the tonnage quantities required for oil fields, while maintaining consistent quality and performance, is a formidable engineering task.

A thorough cost-benefit analysis must demonstrate that producing and implementing these nano-demulsifiers is economically advantageous compared to established, albeit less environmentally friendly, conventional methods when applied across vast and diverse field conditions.

Moreover, any new material introduced into large-scale industrial processes must undergo rigorous long-term environmental and safety assessments to fully understand its lifecycle impact and prevent unforeseen risks.

Addressing these challenges will likely require enhanced collaboration among Iranian researchers, international partners, and the global petroleum industry to standardize testing protocols, share best practices, and refine the technology for commercial viability, paving the way for these green nanotechnologies to realize their full potential on the world stage.

Vision for a cleaner energy future

The development of eco-friendly magnetic nano-demulsifiers by Iranian researchers embodies a compelling fusion of innovation, environmental responsibility, and practical engineering.

By intelligently harnessing the unique properties of nanomaterials and combining them with renewable, benign substances, Iranian scientists have crafted a sophisticated solution to one of the oil industry’s most persistent operational and environmental challenges.

These advancements signal a shift toward a more sustainable model for petroleum processing, where efficiency and ecological care are not mutually exclusive but integrated into the very design of the technology.

As the global community intensifies efforts to reduce the environmental footprint of the energy sector, such innovations offer a hopeful pathway forward.

The work emerging from Iran’s laboratories stands as a clear testament that through focused research and a commitment to sustainability, even the most traditional industries can be reinvented for a cleaner future, led by the subtle power of magnetism and the promise of nanotechnology.

Iranian security forces hunt Mossad agents as police fall to terror attacks

VIDEO | Venezuelans reaffirm their commitment to political unity

VIDEO | India walks diplomatic tightrope after US action in Venezuela

‘State-sanctioned murder’: Netizens rage against US murder of Minneapolis mother

Trump withdraws US from 66 international organizations

Israeli forces abduct four young Syrians after incursion into Syria's Quneitra

Trump says US will oversee Venezuela ‘for years’

Iran FM warns of Israel’s threats to region as he arrives in Lebanon for talks

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website